Function

Basic cover systems work in many ways. The lower, molten part of the cover powder prevents the entrance of the atmospheric gases O2, N2 and H2. The upper, powdery part of the cover powder protects the cast from heat loss. The alkalescence of the molten cover portion allows additional take-up of non-metallic inclusions. The low oxygen partial pressure of the alkaline cover reduces the re-oxydation of steel. There is only minimum change to the saturation point of the alkaline in-line slags from the steel treatment ladles when mixed with alkaline cover powders - this prevents resulphurization of the steel by the saturated in-line slag.

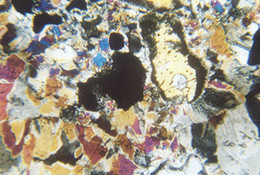

The advantage of applying poly-component systems is that there is no longer a single melting point for the whole cover, so initial eutektical or peritektical partial melting spots arise, while the rest remains solid.

The metallurgical advantages for the steel treatment are:

- High alkalescence

- Low melting point

- High melting speed

- Low oxygen partial pressure (slag becomes desoxydizing)

- Low SiO2 content (no silicating, no oxydation of titan)

- Low carbon content (no carburization)

- Take-up potential for oxydic inclusions

Kinetic reaction formulation mode

The specific grain distribution and material grade of the raw material composition are considered in order to influence the melt open behaviour of slags and cover powders in the desired way. Selecting special grain ranges plus finest alumina fraction upgrading, respectively enriching the CaO in coarse fraction and ensuring a slight exothermal behaviour of the mix are key to the FOR MET product series providing maximum melting speed.

Three factors influence the melt open behaviour of the mix:

- The temperature

- The granulation characteristics

- The material grade