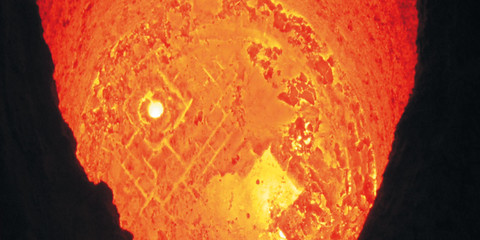

Wear Lining

The advantages of using monolithic hot repair on the wear lining are:

- easy lining

- high insulating effects

- easy removal of skull residues

- no metallurgical influences

- reduced wear of the permanent lining

WEERULIN offers a considerable number of different products for the hot maintenance of the critical areas in the steel ladle. They are all designed to fit the individual ladle philosophy of our customers.

Monolithic Steel Ladle

Following advantages speak for the monolithic technology:

- reduced operational costs

- improved ladle availability

- application in a universal range of grades

- sandwich design

- reduced environmental problems through reduced break-outs

The monolithic steel ladle has established itself beside the standard alternative in the market. On the basis of high quality raw materials WEERULIN has developed monolithic products for application in steel ladles of all sizes.

| Sector | Type | WEERULIN Product | Characteristics |

|---|---|---|---|

| Slag area | gunning mix | FOR MAK GT 2 | sea water magnesite-containing high quality hot repair gunning mix |

| Lip ring | gunning mix | FOR MAK VH 3 | ring maintenance mix for easy de-skulling |

| Walls / bottom | castable | FOR SP 4 B | bauxitic castable for the wear lining |