Water model

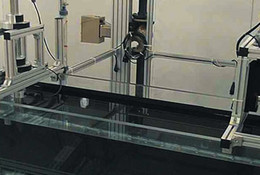

Flow technical measurements in liquid steel casts are impossible to carry out because of the extreme conditions prevailing in steel plants. However, casts of approximately 1500°C and water of approximately 20°C have an almost identical kinematic viscosity, making it easy to obtain revealing results from flow technical test in a water model. The test series was carried out on the model of a 16 tons continuous tundish of a one-beam slab continuous casting plant (scale 1:1.7).

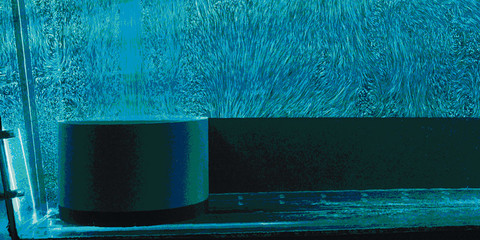

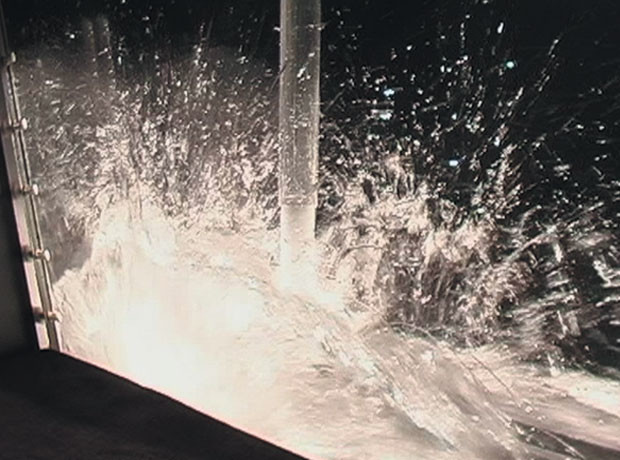

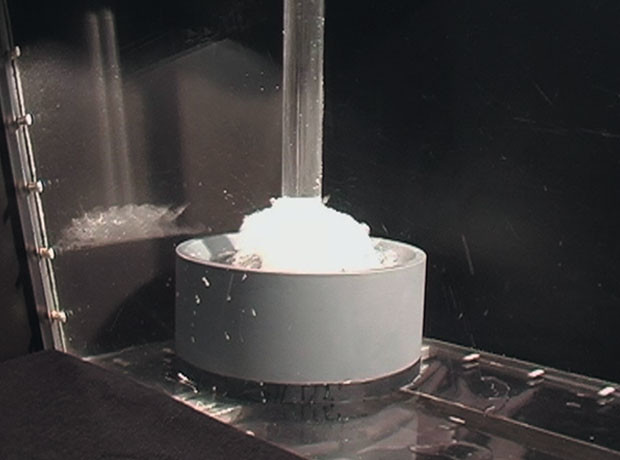

In the runner phase the drum effect of the PowerDrum was simulated by a steel cover with an opening. The result was a considerable reduction in splashing. Visualization of the flow structures was done using a laser light section system.

Small plastic particles, that would follow the flow inertia-free, were added to show how the particles moved.